During the period of analysis, Mexico was one of the three main actors in the DVA trade network for global manufacturing exports. Compared to the textiles industry, which is a more important export sector, the automotive industry has not followed the same path. Both industries are key players in Mexico's export market, and they are still relevant to job generation in Mexico.

The Mexican automotive sector is one of America's largest suppliers of auto parts. It is also one among the fastest-growing industries in Mexico. It hasn't been able pull the rest the economy on a high growth trajectory. The automotive industry is moving from being a domestic-oriented business to becoming a regional auto parts/automobile company. This transition is a result of a combination international direct investment and regional processes.

Mexico's special programs for development have been a boon to the automotive industry. It has become the leading supplier of auto parts for the U.S. and has achieved spectacular penetration into world markets. It also has received foreign direct investment which has helped to increase its position in global value chains.

The Mexican automotive industry is also a key player in the GVCs of Europe and the United States. Mexico's automobile industry was an integral part of Mexico’s economy in the 1970s, 1980s. However, it has not been as well-recognized on the international market as the textile trade. It has not been able expand its output at a rapid pace, but it has seen remarkable penetration on the world market.

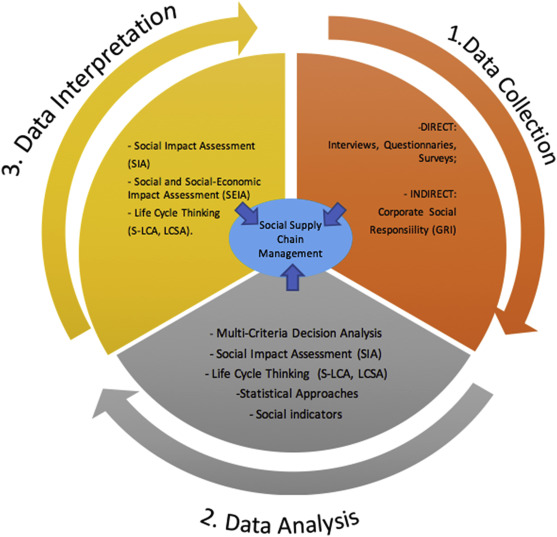

This study analyzes the relationship between international labour and Mexican labor in the manufacturing sector. It uses the framework for decent work indicators, which was developed by the International Labour Organization (ILO). The indicators are based primarily on official data and consider the interconnections between Mexico's labor regulations and trade agreements. The input-output analysis for international trade is included as well. It shows that Mexico only plays a very small role in global manufacturing exports’ domestic value-added.

The study also examines whether trade liberalization has had an impact on Mexican manufacturing jobs. The study uses the System of National Accounts framework to construct a set of decent-work indicators for two industries in Mexico: textiles and transport equipment. These indicators are compiled into a time series and used to analyze the Mexican evolution of decent employment. The study found that the level D V A V C in Mexico's manufacturing sector is much lower than the textile sector. Similar to the textile sector, the study shows that the level in which the employment in automotive is higher than the textile sector's is also lower. The study also shows that real wages have declined over the period of the analysis. In other words, nominal wage adjustments were not sufficient to compensate real wage declines. The study shows that DVA in exports for transport equipment has increased in recent years, while DVA has decreased in exports for textiles.

FAQ

What skills should a production planner have?

Being a production planner is not easy. You need to be organized and flexible. Also, you must be able and willing to communicate with clients and coworkers.

What makes a production planner different from a project manger?

The difference between a product planner and project manager is that a planer is typically the one who organizes and plans the entire project. A production planner, however, is mostly involved in the planning stages.

What is the job of a logistics manger?

Logistics managers are responsible for ensuring that all goods arrive in perfect condition and on time. This is done by using his/her experience and knowledge of the company's products. He/she should ensure that sufficient stock is available in order to meet customer demand.

What are the jobs in logistics?

Logistics can offer many different jobs. Some examples are:

-

Warehouse workers – They load, unload and transport pallets and trucks.

-

Transportation drivers – These drivers drive trucks and wagons to transport goods and pick up the goods.

-

Freight handlers are people who sort and pack freight into warehouses.

-

Inventory managers – These people oversee inventory at warehouses.

-

Sales reps are people who sell products to customers.

-

Logistics coordinators - They organize and plan logistics operations.

-

Purchasing agents - They buy goods and services that are necessary for company operations.

-

Customer service representatives – They answer emails and phone calls from customers.

-

Shipping clerks – They process shipping orders, and issue bills.

-

Order fillers: They fill orders based off what has been ordered and shipped.

-

Quality control inspectors – They inspect incoming and outgoing products to ensure that there are no defects.

-

Others - There are many types of jobs in logistics such as transport supervisors and cargo specialists.

Is automation important for manufacturing?

Not only are service providers and manufacturers important, but so is automation. They can provide services more quickly and efficiently thanks to automation. It reduces human errors and improves productivity, which in turn helps them lower their costs.

Statistics

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

External Links

How To

Six Sigma: How to Use it in Manufacturing

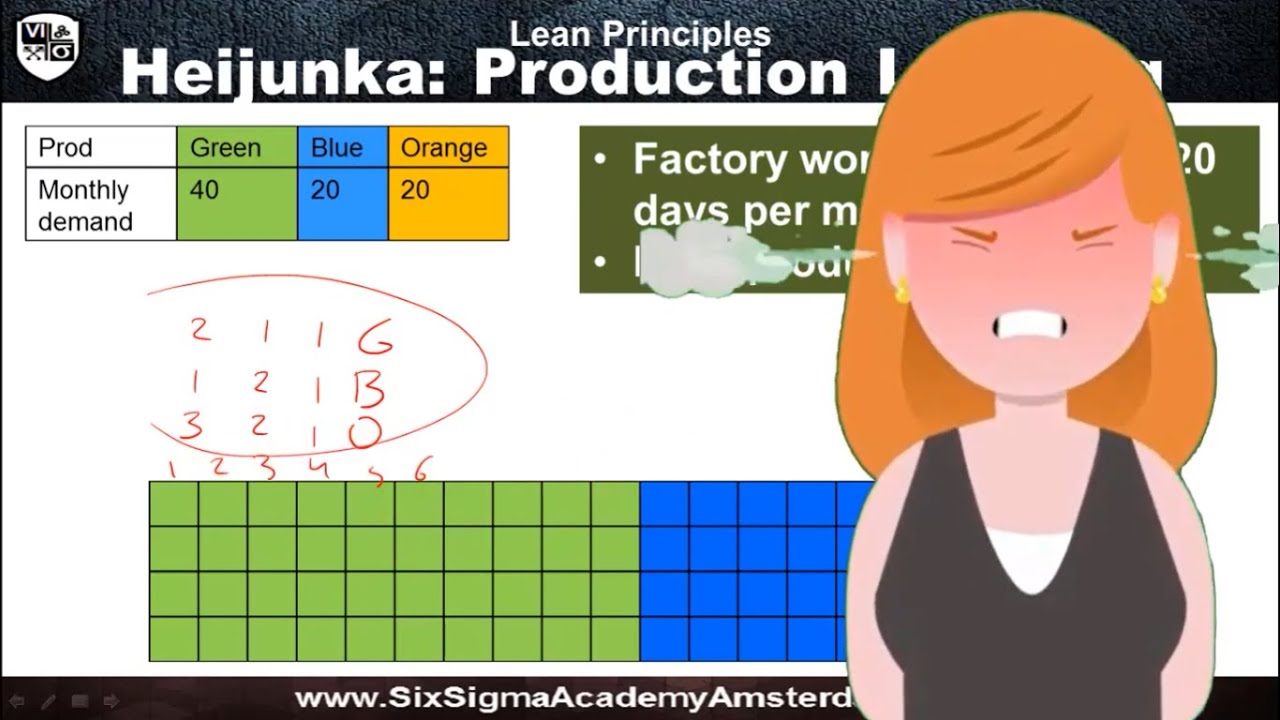

Six Sigma is defined as "the application of statistical process control (SPC) techniques to achieve continuous improvement." Motorola's Quality Improvement Department, Tokyo, Japan, developed it in 1986. Six Sigma's basic concept is to improve quality and eliminate defects through standardization. Many companies have adopted Six Sigma in recent years because they believe that there are no perfect products and services. Six Sigma seeks to reduce variation between the mean production value. This means that you can take a sample from your product and then compare its performance to the average to find out how often the process differs from the norm. If the deviation is excessive, it's likely that something needs to be fixed.

Understanding how variability works in your company is the first step to Six Sigma. Once you have a good understanding of the basics, you can identify potential sources of variation. It is important to identify whether the variations are random or systemic. Random variations are caused when people make mistakes. While systematic variations are caused outside of the process, they can occur. Random variations would include, for example, the failure of some widgets to fall from the assembly line. However, if you notice that every time you assemble a widget, it always falls apart at exactly the same place, then that would be a systematic problem.

Once you've identified the problem areas you need to find solutions. The solution could involve changing how you do things, or redesigning your entire process. Once you have implemented the changes, it is important to test them again to ensure they work. If they fail, you can go back to the drawing board to come up with a different plan.