Knowing what to expect is key to earning a Supply Chain Management Certificate. This degree program was designed for working professionals. It emphasizes case material, simulations, experiential learning, and other relevant topics. During your coursework you'll work with industry experts and peers in supply chain. The final project or capstone project will require you to work with a company to solve a problem. If you're unsure of whether this degree is right for you, read on to learn more about how to find the best program for you.

Coursework

The Coursework for Supply Chain Management Certificate covers four courses. It will cover the basic concepts of the field. This program covers topics such customer demand forecasting as well as master production scheduling, inventory planning, capacity planning and capacity planning. The program provides the necessary information to pass supply chain management certification exams. Students will learn how to implement practical solutions to improve performance and save money. The curriculum will also provide an overview of supply chains management and the key drivers.

To obtain this certification, students must take the required courses and pass the certificate exam. The American Production and Inventory Control Society, the industry standard, administers the exam. Companies in the manufacturing and supply chain management sectors will look for APICS certification when hiring new employees. The 12 credit semesters of the course are full-time. Students who are accepted into the program must submit a resume, interview and transcript with the Grainger Center staff to complete their degree.

Prerequisites

To pursue a certificate in supply chain management, you must have the appropriate prerequisites. Whether you are an experienced supply chain management professional or a graduate of a general management program, this certificate is designed for you. This certificate prepares you for the certification exam. You'll also learn how to manage inventory, create demand forecasts, and control production orders. This course emphasizes key performance indicators such customer satisfaction as well as environmental impact.

The prerequisites for this certificate will vary depending on where you plan to complete the program. A bachelor's degree is required in business or supply-chain management. However individuals with no SCM experience are welcome to apply. It's best to talk with your advisor if you are unsure if a particular degree is necessary. Although the prerequisite courses will give a solid foundation of supply chain management, it is worth considering electives to make your education more tailored to your specific needs.

Certifications

A supply chain management certification is a great way for you to advance your career. The majority of supply chain certifications can be based on real-world scenarios. They can also be practical and helpful, as they allow you to show your expertise. These certifications work best for students in the early stages of supply chain management who still want to learn. Here are some examples supply chain certifications. Learn more. We've outlined some of the more common certifications and what they mean for you.

ASCM credential Certified in Production and Inventory Management is the CPIM certification. This certification shows that supply chain managers have extensive knowledge in inventory control and operations. This certification requires you to pass two exams within three year. The CPIM Part 1 exam focuses primarily in the foundations of supply management. The CPIM Part 2 exam focuses mainly upon scheduling, resources and the overall operation a supply supply chain. Remember that the CPIM Certification requires candidates to earn 75 professional developmental points.

Internships

An internship certificate in supply-chain management is a great start for someone who wants to work in a related field. The supply chain is not as easy to set up and forget like other types jobs. Every business has its own unique set of processes and capabilities, and the same applies for a supply chain at a trucking company. Supply chain internships give students hands-on experience and help them to develop practical skills.

Students who wish to earn supply chain management certificate internships need to be careful not to neglect their studies. A high GPA is a good sign of drive, focus, and smarts. An impressive resume and interpersonal skills can also boost one's chances. An advisor at college can help you polish your resume. But, it is possible to translate skills from one language in another. This can make it difficult. It is best to consult a career adviser as well as a college advisor.

FAQ

What can I do to learn more about manufacturing?

You can learn the most about manufacturing by getting involved in it. But if that is not possible you can always read books and watch educational videos.

What is the role of a production manager?

Production planners ensure that all project aspects are completed on time, within budget and within the scope. A production planner ensures that the service and product meet the client's expectations.

Why automate your factory?

Modern warehousing has seen automation take center stage. The rise of e-commerce has led to increased demand for faster delivery times and more efficient processes.

Warehouses must be able to quickly adapt to changing demands. Technology is essential for warehouses to be able to adapt quickly to changing needs. Automation warehouses can bring many benefits. Here are some of the reasons automation is worth your investment:

-

Increases throughput/productivity

-

Reduces errors

-

Increases accuracy

-

Safety Boosts

-

Eliminates bottlenecks

-

Allows companies to scale more easily

-

It makes workers more efficient

-

It gives visibility to everything that happens inside the warehouse

-

Enhances customer experience

-

Improves employee satisfaction

-

Reduces downtime and improves uptime

-

This ensures that quality products are delivered promptly

-

Human error can be eliminated

-

Helps ensure compliance with regulations

Statistics

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

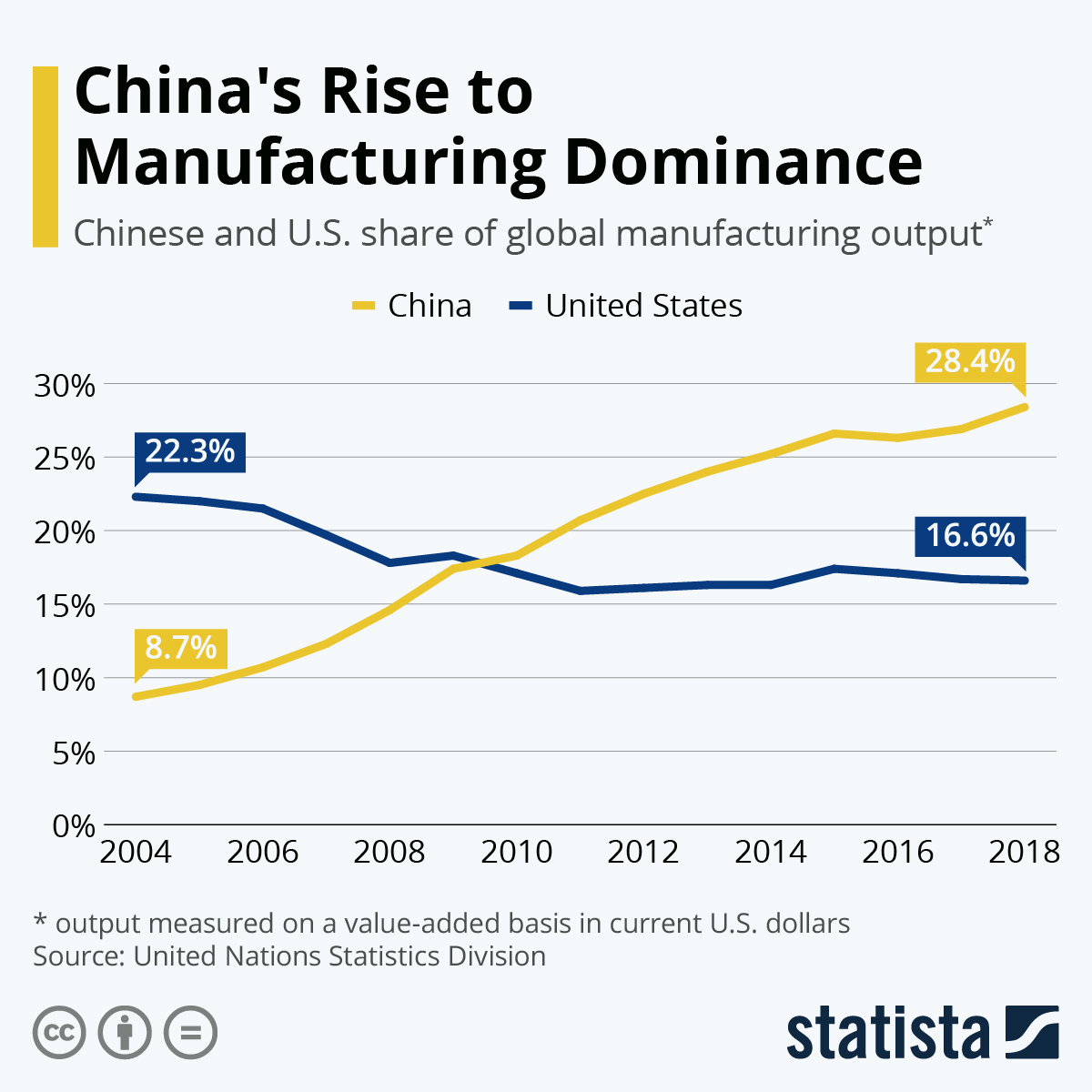

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

External Links

How To

How to use 5S to increase Productivity in Manufacturing

5S stands to stand for "Sort", “Set In Order", “Standardize", and "Store". Toyota Motor Corporation developed the 5S method in 1954. It improves the work environment and helps companies to achieve greater efficiency.

This method aims to standardize production processes so that they are repeatable, measurable and predictable. This means that daily tasks such as cleaning and sorting, storage, packing, labeling, and packaging are possible. This knowledge allows workers to be more efficient in their work because they are aware of what to expect.

There are five steps that you need to follow in order to implement 5S. Each step requires a different action, which increases efficiency. For example, when you sort things, you make them easy to find later. When items are ordered, they are put together. You then organize your inventory in groups. Labeling your containers will ensure that everything is correctly labeled.

This requires employees to critically evaluate how they work. Employees need to understand the reasons they do certain jobs and determine if there is a better way. To implement the 5S system, employees must acquire new skills and techniques.

The 5S method increases efficiency and morale among employees. As they begin to see improvements, they feel motivated to continue working towards the goal of achieving higher levels of efficiency.